Service

We can make both prototype injection molds and regular plastic injection molds , For the new developed items, sometimes our clients firstly will make a prototype injection mold to test and verify the design ,the resin flowability and the injection stability etc, this can helps our clients to find the problem of the design and selection of plastic materials and reduce the risk of new items production and the cost waste due to the design problem. after all problem settled down, our clients will ask us to upgrade or modify the prototype mold to the formal mold.

Our accracy of the prototypes injection molds is same with the regular molds, so it is advantage to build a prototype mold to launch small batch of the new products to market. As the lead time of the prototype injection molds is much shorter and the cost is much cheaper than the regular molds.

Our molds building services is foucs on high precision automotive structural parts and high precision parts which used in the equipment or instrument of the medical and communication industry.

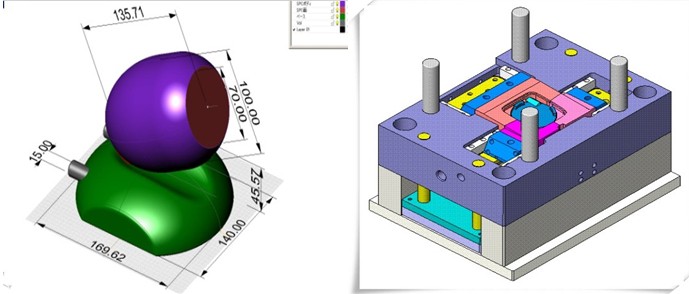

Prototype injection molds

We have rich experience in Prototype mold manufacturing, We have know-how to make high precision mold in very short lead-time at low-cost . This can help our customer keep competition advantage in the market. Some of our customer are well-known enterprises like Panasonic, Honda, Toyoda, BMW, etc.

The advantage of the injection molded prototypes are:

-Quality level similar with traditional mold

-Same plastic materials as the one using in mass production

-Save overall development cost

-Test and Verification of the plastic parts design

-Test and Verification of the mold design

-Test and Verification of the resin flowability

-Test and Verification of the Function

-Lunch the new product to the market quickly at short leadtime

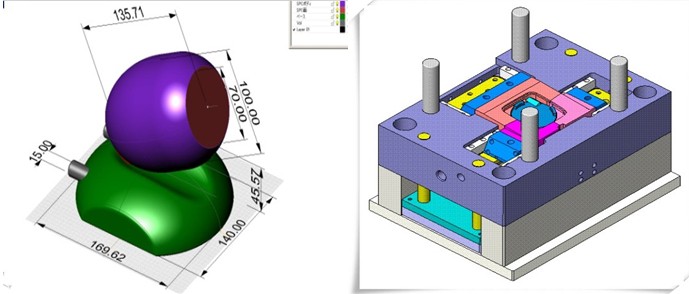

Plastic injection molds

The making of plastic injection molds has been our core business for over 10 years. Our focus is on the molded parts for automotive, medical instruments, hobby product and some high precision industrial parts

-Mold design

1,Good molds design can prevent those problems may happened during production, We have been in manufacturing industry for more than 20 years by now, We know what kind of quality problems often occur in production, we will try to avoid it in mold design ,we have know-how to offer our client with the most cost effective and safe mold design.

2, Available file formats for your 3D data.

We support multiple file formats including major software such as:Solidworks, UG, ProE, Catia,, STEP, SAT, IGES.

-Mold Fabrication

We has high precision processing machines, such as MIKRON CNC, Milling Machine Center, Mirror EDM, Wire Cut Machine etc.

Skillful staff have been highly trained, most of them with over 7 years of experience in mold manufacturing.

Mold capabilities:

1)Max size:

Length 1.5m * Width 1.5m

Mold life.:MAX5000,000 Shot

2)Mold type

1, 3 plate molds

2, Overmolds

3, Double-shot injection molds

4, Insert molds

5, Runner type:Hot/Cold

3)Mold type(by application)

Automotive Mould

Industrial Parts mould

Electronic Product Mould

Household Mould

Toy Mould

4) Most often be used mold materials

#718,NAK80, S136

5)Materials for plastic injection molding

PA,PC,PP,PE,ABS,Nylon,POM,PC,PVC,

TPE,PCABS,TPV,TPU,PS,PMMA,ABS+PC, TPE, TPR, ASA, PA+GF etc.